| Sold |

| My Conversion |

| Our Memories |

| Select Monitor |

| Links |

|

VWRX.com

- Volkswagen Vanagon powered by Subaru WRX STi Turbo engine

|

KEP Adapter Plate ImprovementsOn some of the earlier KEP adapter plates there were reportedly some lower studs breaking when using a Smallcar mount. There were several factors contributing to these failures, but I feel the most significant causes for these failures are as follows (in order of importance):

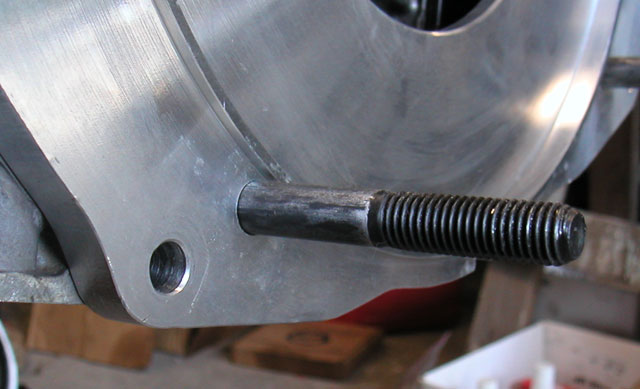

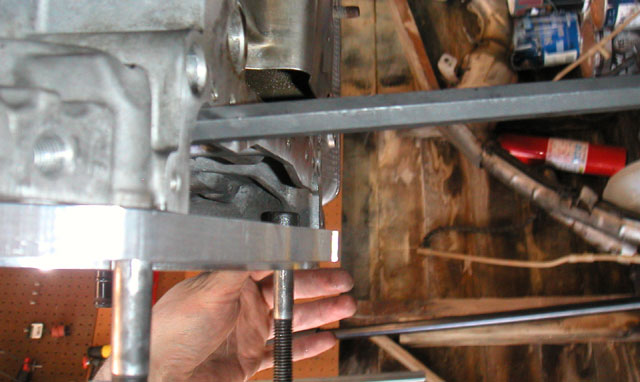

1.) 10mm studs are too small. The improvements I made to my adapter plate and bell housing have addressed all four of these issues. First I replaced the bottom two 10mm studs with 12mm class 12.9 (grade 10) bolts. The holes in the adapter plate were drilled out and the new bolts were press fitted into place.  The only class 12.9 bolts I could find were with socket heads.  This actually worked out perfect. I just had to cut down and modify a normal hex key wrench.  With the new modified tool, access to the bolt head from the bottom is pretty easy.  The little notches in the access hole almost seem like they were designed for this purpose.  The upper stud opposite side of the starter was replaced with a class 10.9 (grade 8 ) bolt. It was also pressed into place like the lower studs. I used a hex head bolt here since access is a bit more tricky.  As you can see, access to the head can be gained through the access hole on the top of the block.  Using a standard size 19mm wrench in the bottom access hole and a finger in the top access hole, it's pretty easy to get a wrench on the bolt head.  Since all these studs are pressed in, not much force is be needed to hold the end of the bolts. For the upper stud that goes through the starter I kept the original 10mm stud. This is because the nut required on a 12mm is too big and will interfere with the starter. The hole in the bell housing for this stud however is about about 13.5mm, so decided to sleeve the stud to 12.8mm for a tighter fit. The entire non-threaded portion of the stud is sleeved.  The other three holes in the bell housing were drilled out with a 12mm drill bit. This creates a very tight fit since the 12mm bolts are about 11.85mm in actual diameter. The adapter plate now has literally zero movement of play on the bell housing. In addition to these improvements, I decided to use the 8mm alignment hole in the bottom of the bell housing as an additional fastening point. Unfortunately the KEP adapter plate doesn't completely cover this hole. I assume the odd shape of the bottom of the adapter plate was designed this way to accommodate something unique about the 2WD transaxles? I drilled out the 8mm hole in the bell housing and tapped it for a 10mm bolt. Then notched the bottom of the adapter plate.  As you can see, more than half of the 10mm bolt will be inside the plate.  The intent here is really to just help things out a bit. With a washer the bolt has a pretty good contact area on the plate.  The new lower center bolt is a class 10.9 (grade 8 ) bolt and is torqued to about 20 ft-lbs. The other three new studs are torqued to about 36 ft-lbs and the starter stud is torqued to something slightly less.  Here's some technical data for anyone considering using larger bolts on their adapter plate. Shear strength of a bolt is typically about 60% of the ultimate tensile strength. A class 8.8 bolt has a tensile strength of 120,000psi A class 10.9 bolt has a tensile strength of 150,000psi A class 12.9 bolt has a tensile strength of 177,000psi Using the cross sectional area of the bolt (Pi x r2) the following shear strength capabilities can be calculated:

10mm class 8.8 = 8568 lbs As you can see, a 12mm class 12.9 bolt has over twice the shear strength capability then 10mm class 8.8 bolt. |